Have you ever wondered about the hidden helpers behind the things you buy every day? It's almost like a quiet agreement in the business world, where some companies focus on making the individual pieces, and others bring those pieces together to create something bigger. This way of working is really common, especially with gadgets, cars, or even the software on your computer.

So, when we talk about how products come to be, it turns out many of the items we use are put together from bits and pieces made by different specialized businesses. Think of it like a giant puzzle, where each piece is crafted by someone good at that particular part. The company whose name is on the final box often gets those crucial parts from other places, and those other places have a special name in the industry.

This whole idea points to a kind of partnership, where one company makes the foundational items—be they physical bits or even software code—that another company then takes, perhaps adds a few more things, and then sells under its very own brand. It helps a lot of businesses focus on what they do best, whether that's inventing new parts or bringing a complete item to market. You know, it's a pretty smart way to get things done.

Table of Contents

- What is an Original Equipment Manufacturer, Really?

- How Does an OEM Help Other Companies?

- What Kinds of Products Do OEMs Create?

- How is an OEM Different from a Regular Manufacturer?

What is an Original Equipment Manufacturer, Really?

So, an original equipment manufacturer, or OEM as people often say, is essentially a business that creates things—those things could be little bits and pieces, or even bigger parts—that other companies then use inside their own finished items. It's almost like they're the secret ingredient suppliers, making sure the main company has all the right bits to put their product together. You know, if you think about a car, the company that sells you the car probably didn't make every single screw or the entire engine themselves. They got many of those vital parts from other specialized companies, and those specialized companies are often what we call OEMs.

This kind of company produces parts and equipment that may be marketed by another company, which is a pretty key point. What they make isn't always sold directly to you, the person buying the final product. Instead, it goes to another business that then puts its own name on it. It’s like a behind-the-scenes operation, really. They might make a specific kind of screen for a phone, or a certain type of computer chip, and then the well-known phone or computer company buys it, puts it into their device, and sells it as their own creation. This arrangement helps a lot of businesses.

An original equipment manufacturer is a company that produces hardware or software that is later marketed and sold under another company's brand. This means the items they make, whether they are physical bits you can hold or lines of code, become part of someone else's branded item. It’s a bit like a ghostwriter for products, if you will. The original maker does the hard work of creating the item, but the credit for the final product goes to the company that sells it to the public. This arrangement is, in a way, about efficiency and specialization in the making process.

The term "OEM" stands for original equipment manufacturer and was initially used to refer to a company that made a product that was rebranded and resold by another company. This historical usage helps us get a better sense of the core idea. It’s not just about making a part; it's about making something that another business will put its own stamp on and then sell as if it were their own complete item. It’s a practice that goes back quite a while, and it has evolved a bit, but the fundamental idea remains the same: one maker, another seller, and a rebrand in between. So, that's basically the starting point for understanding this whole concept.

The meaning of OEM is one that produces complex equipment, such as a computer system, from components usually bought from other manufacturers. This adds another layer to the idea. An OEM isn't just making a simple screw; they might be putting together something quite intricate, like a whole computer motherboard or a complex software module, using parts they themselves sourced from other places. It's a chain of creation, where one OEM might even be a customer of another OEM. It’s a very interconnected way of building things, really, allowing for a lot of specialization at each step of the way.

OEM, short for original equipment manufacturer, refers to a company that produces components or products that are purchased by another company and then retailed under that purchasing company's name. This is, in essence, the clearest way to put it. The company doing the buying isn't just getting a raw material; they are getting a finished or nearly finished piece that they can then integrate into their own product line and sell as their own. It helps companies focus on their strengths, whether that's designing the overall product or handling the sales and marketing side of things. It’s a pretty clever system, if you think about it.

Getting the Core of OEM Meaning

At its core, an original equipment manufacturer refers to a company that produces parts, components, or complete products that are used in the final assembly of a larger system. This definition really gets to the heart of what an OEM does. They are the builders of the building blocks. Without these specialized makers, many of the big companies we know wouldn't be able to put together their impressive products as efficiently or affordably. It's a foundational role, basically, in how many modern goods come into being. They are, in a way, the silent partners in product creation.

An original equipment manufacturer is a company that designs and produces components or products that another company then sells under its branding. This means the OEM isn't just following instructions; they might also be involved in the design process, bringing their own expertise to the table. They create something specific, and then another business takes that creation and puts its own label on it for sale to the public. It’s a very common practice, especially in fields where specialized knowledge for making certain parts is very valuable. You know, it helps spread out the work.

How Does an OEM Help Other Companies?

So, how does an OEM actually help other companies? Well, it's about efficiency and focus, really. When a company uses an OEM, they don't have to build every single piece of their product from scratch. Imagine a car company trying to make every single bolt, every piece of glass, every tire, and every engine component themselves. It would be incredibly difficult and expensive. Instead, they rely on OEMs who specialize in making just those things, often at a much larger scale and with greater expertise. This lets the main company put its energy into designing the overall car, marketing it, and selling it to customers. It’s a bit like delegating tasks to experts.

One big way OEMs help is by allowing businesses to save money. Setting up factories and processes to make every single part of a complex product can be a huge investment. By buying parts from an OEM, a company can avoid those upfront costs. The OEM already has the machinery, the skilled workers, and the know-how to produce those specific items efficiently. This can make the final product more affordable for everyone, which is pretty important for customers. It means better prices, in a way, for what you buy.

Another benefit is getting products to market faster. If a company wants to launch a new item, and they need a specific component, they don't have to spend years developing that component themselves. They can just buy it from an OEM that already makes it or can quickly adapt to make it. This speeds up the whole process of bringing new products to people, which is very helpful in today's fast-moving world. It's about being nimble, basically, and getting things done quickly.

OEMs also provide specialized knowledge. Some parts or software pieces are incredibly complex to make. Companies that specialize in these areas, the OEMs, have deep expertise and experience. They know all the little tricks and details to make sure those parts work perfectly. When another company buys from them, they are also getting the benefit of all that specialized knowledge without having to develop it themselves. It's like getting a ready-made solution from someone who truly knows their stuff, which is a big advantage.

The Value Behind OEM Meaning

The value behind OEM meaning is quite clear when you consider how many products are built this way. It's a fundamental part of the manufacturing industry because it allows for a division of labor that makes everything more efficient. Companies can focus on their brand identity, their overall product design, and their sales strategies, leaving the intricate details of component production to others. This kind of arrangement helps businesses grow and innovate without having to become experts in every single aspect of production. It's a practical way to manage large-scale making processes, basically, and it supports a lot of different industries.

What Kinds of Products Do OEMs Create?

So, what sorts of things do OEMs actually make? The range is incredibly wide, really. It’s not just about tiny screws or simple wires. OEMs produce everything from highly complex computer system components to entire pieces of software. For example, think about a personal computer. The company whose name is on the outside of the computer box probably didn't make the processor chip, the memory modules, or the hard drive. Those vital parts are often made by OEMs who specialize in those very specific technologies. They are, in a way, the backbone of the tech world, providing the guts for many of our favorite gadgets.

In the world of electronics, OEMs are responsible for making things like circuit boards, power supplies, display screens, and even the tiny cameras found in phones. These are all highly specialized items that require particular skills and equipment to produce. A company that sells a complete smartphone will buy these components from various OEMs and then assemble them into the final product. It’s a very common practice, and it ensures that each part is made by a maker who is truly focused on that one thing, which is pretty cool.

It's not just hardware, either. OEMs also produce software. For instance, a company might create a specialized operating system component or a specific piece of software that another company then bundles with its hardware or integrates into its own larger software package. This is often seen with things like drivers for computer parts or specific applications that come pre-installed on a new device. The software OEM develops the code, and the other company distributes it under their own brand. This helps ensure compatibility and adds features without the main company having to write all the code themselves, which is very helpful.

Sometimes, an OEM might even produce a complete product that is then simply rebranded. Imagine a small appliance, like a toaster or a coffee maker. A large brand might not have its own toaster factory. Instead, they might contract with an OEM that specializes in making small kitchen appliances. The OEM makes the toaster, and the larger brand puts its name on it, handles the marketing, and sells it in stores. This is a very efficient way for brands to offer a wide range of products without having to build a separate factory for every single item. It’s a bit like white-labeling, in a way, for physical goods.

Broadening Our View of OEM Meaning

Broadening our view of OEM meaning, we see that these companies are incredibly versatile. They can produce almost anything that can be used as a component or a complete item for another business to sell. This flexibility is what makes them so important to the global economy. They fill specific niches, provide expertise, and allow other companies to scale their offerings quickly and effectively. Without them, many of the products we rely on daily might not exist, or at least not at the prices we are used to. They are, essentially, the unsung heroes of product creation.

How is an OEM Different from a Regular Manufacturer?

So, how exactly is an OEM different from what we might call a "regular" manufacturer? This is a pretty important distinction to make clear. A regular manufacturer typically makes products and then sells them directly to consumers or through their own established sales channels, like their own stores or website, or perhaps through big retail chains under their own brand name. They are in charge of the whole journey, from making the item to getting it into your hands. You know, they own the brand and the direct relationship with the person buying the item.

An OEM, on the other hand, operates a bit differently. Their main customer isn't usually the end-user. Instead, their customer is another business. The OEM produces components or entire products that are then purchased by this other company, which then takes on the role of selling it to the final customer. The key difference lies in the branding and the sales channel. The OEM's name might not appear on the final product you buy. It’s the purchasing company's brand that gets the spotlight. It’s a very business-to-business kind of relationship, basically.

Think of it this way: a company like Intel makes computer processors. They are an OEM. You don't buy an Intel processor directly from Intel to put into your computer, generally speaking. You buy a computer from a brand like Dell or HP, and that computer has an Intel processor inside. Dell or HP are the ones selling the complete computer to you, with their brand on it. Intel, the OEM, sold the processor to Dell or HP. This is a pretty classic example of how the OEM model works in practice. It’s all about who sells to whom, and whose name is on the box.

Another way to look at it is that OEMs are often specialized in making specific kinds of parts or products in very large quantities. Their business model is built around efficient production for other businesses, rather than direct consumer sales and marketing. A regular manufacturer, by contrast, needs to invest heavily in marketing, branding, and distribution networks to reach individual buyers. OEMs can focus solely on making excellent products for their business clients, which is a big part of their appeal. It’s a very focused approach to making things.

Making Clear the OEM Meaning

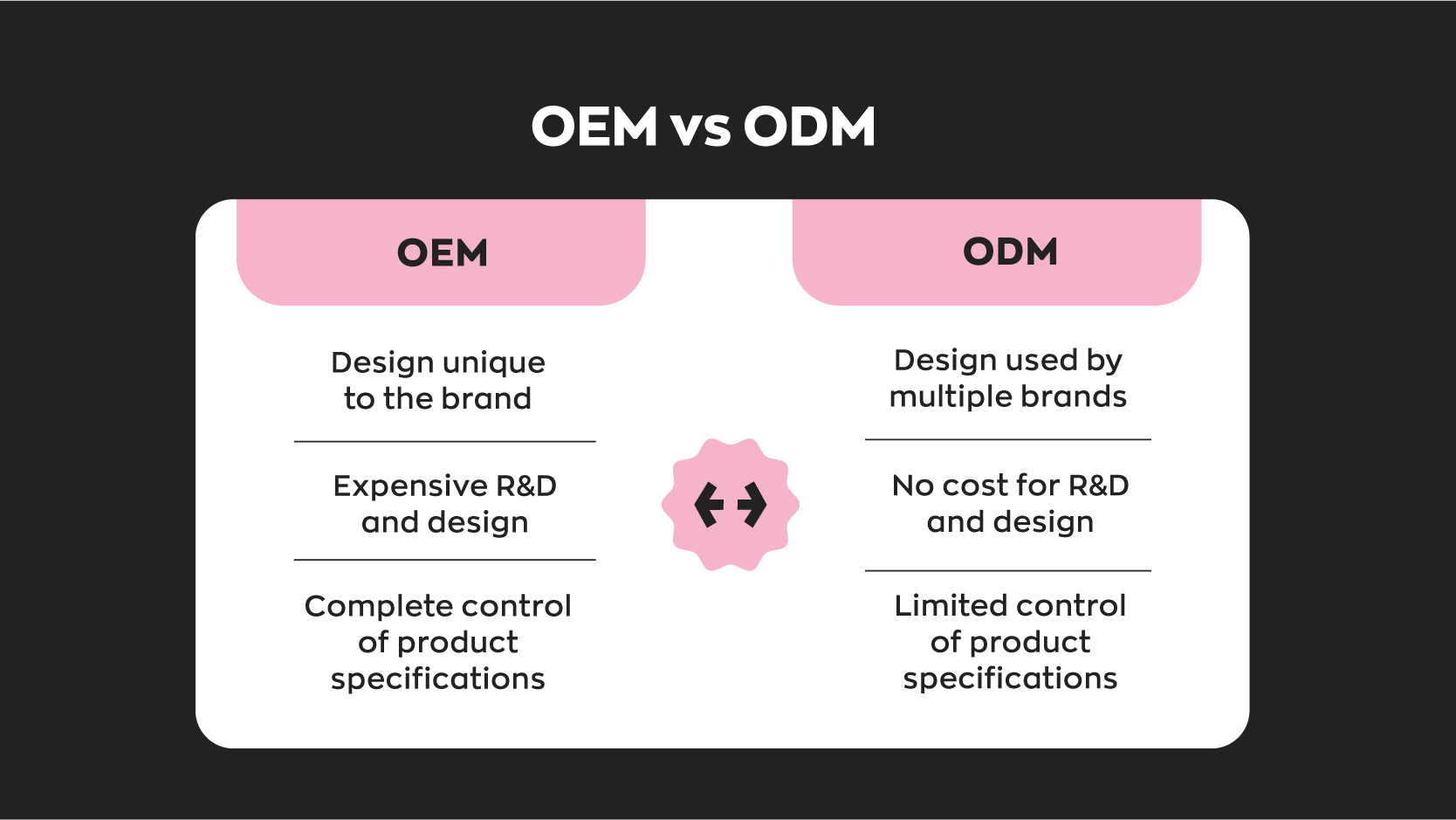

Making clear the OEM meaning really helps us see how different parts of the economy fit together. It highlights that the process of creating and selling products is often a collaborative effort between many specialized companies. The OEM is a company that manufactures and sells products or parts of a product that their buyer, another company, sells to its own customers while putting their own brand on it. This division of labor allows for greater efficiency, lower costs, and more innovation across various industries. It’s a term used in the manufacturing industry to describe companies that produce components or products that are sold to other companies, basically. It’s a system that truly supports how many of the things we use daily come into being.

:max_bytes(150000):strip_icc()/OEM-736beaf9c8b544ec9f86acc5bc3ca490.jpg)