For anyone looking into the world of creative fabrication, or perhaps just starting out with computer-controlled tools, Langmuir Systems often comes up in conversation. It is a company that has, in some respects, really made a name for itself by helping people bring their ideas to life with precise metal cutting and shaping equipment. From hobbyists to those running small shops, the tools they offer aim to make sophisticated processes more accessible, allowing individuals to explore their making potential.

Many folks who choose Langmuir Systems do so for a few good reasons, and a big one seems to be the community that has grown up around their products. People often talk about how helpful and active the online discussions are, making it easier for new users to get started or for experienced users to share what they know. It's really about people helping people, which is pretty cool, you know, especially when you're learning something new that might seem a little complex at first.

When you get a new piece of machinery, like a CrossFire XR plasma table or a Titan press brake, there are always questions. How do you set it up? What kind of extras do you need? How do you get the best results? Langmuir Systems and its community seem to work together to answer these things, making the whole experience of owning and operating their equipment a lot smoother for everyone involved, which is actually quite reassuring.

Table of Contents

- Welcome to the Langmuir Systems Family

- How Does the Langmuir Systems Community Help Newcomers?

- What About Installing a Torch Height Control with Langmuir Systems?

- Getting Ready for Your Langmuir Systems Machine - What Tools Might You Need?

- Exploring the Langmuir Systems Torch Height Control Module

- What is New with the Langmuir Systems Titan 25T CNC Press Brake?

- How Does a Partnership Benefit Langmuir Systems Customers?

- Are There Common Issues with Langmuir Systems Software Updates?

Welcome to the Langmuir Systems Family

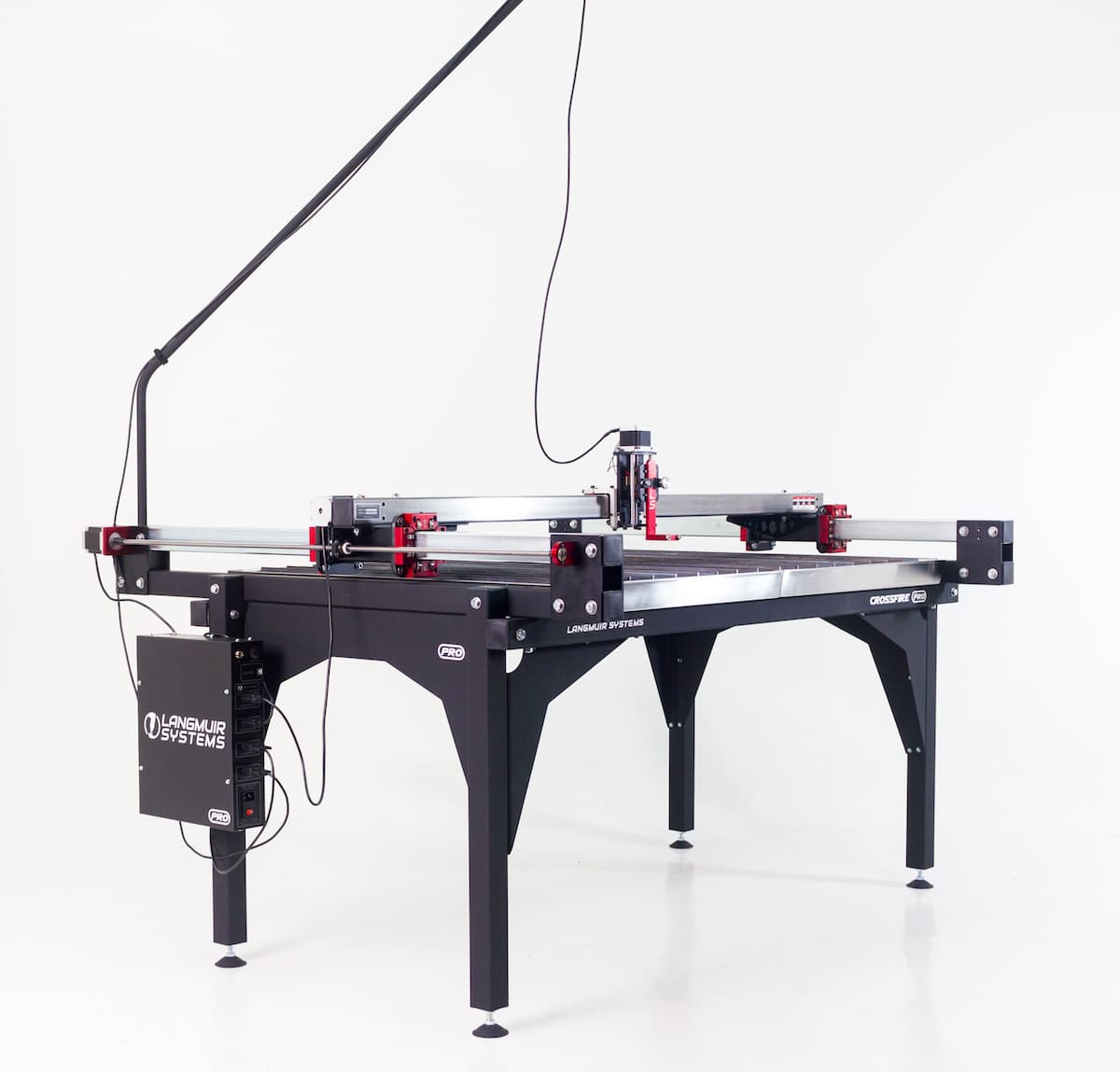

It seems many individuals, just like one person mentioned, are finding their way to Langmuir Systems and getting their hands on equipment like the CrossFire XR. There is a sense of excitement that comes with ordering a new machine, a tool that lets you shape metal with precision, and it is that kind of feeling that draws people in. People often speak about their initial experiences, and how they become part of this growing group of makers. The decision to choose Langmuir, in some cases, comes down to the stories and shared experiences they hear from others who are already using the equipment, which is pretty compelling.

For those who are new to this particular kind of machinery, there is a whole new world of things to learn. From getting the machine unboxed and put together, to understanding how to make your first precise cuts, it can be a bit of a process. Yet, the appeal of being able to create metal parts, whether for a personal project or for a small business, is very strong. It is almost like getting a key to a workshop filled with possibilities, and that is a truly exciting prospect for many.

The first steps with any new piece of equipment are always memorable, and with something like a plasma table, it is about setting up a space where ideas can become tangible objects. People often share their initial thoughts and plans, talking about what they hope to build or what kinds of things they are looking to make. It is a fresh start, in a way, for creative endeavors, and that is a pretty good feeling to have, you know, when you are starting something new.

How Does the Langmuir Systems Community Help Newcomers?

One of the big reasons some people choose Langmuir Systems is because of the online community, specifically the forum. It is a place where people who own or are interested in these machines can talk to each other, share what they have learned, and ask for help. This kind of shared space is actually very helpful for those who are just starting out, or even for those who have been using the machines for a while but run into something new. The forum seems to be a central spot for people to connect, and that is really what makes it special.

Sometimes, when a discussion gets going about a specific topic, like how to tell the difference between certain types of plasma cutters, the information can get spread out. It is pretty useful, therefore, when someone takes the time to gather that information and put it in one spot, helping to clear up any confusion for others. This sort of effort, where people organize shared knowledge, shows how much the community cares about helping everyone get the most out of their Langmuir Systems equipment. It is almost like a big group project where everyone contributes a little something, which is quite nice.

Having a place where questions can be asked and answered by people who have real-world experience is a huge plus. It means that if you are wondering about something, chances are someone else has already figured it out, or they can help you think through it. This kind of mutual support makes learning about and using these machines a much more pleasant experience, and it is a big part of why people feel good about being part of the Langmuir Systems user group. It is, in some respects, a very supportive environment.

What About Installing a Torch Height Control with Langmuir Systems?

Many folks who use computer-controlled plasma cutters, like those from Langmuir Systems, are often keen to get their torch height control working just right. This particular feature helps the machine keep the cutting torch at the proper distance from the metal, which is pretty important for getting clean, consistent cuts. People frequently look for step-by-step guides or wiring diagrams to help them put these parts in place. It is a common topic of discussion among users, as getting it set up correctly can make a big difference in the quality of the work.

It seems that while there are many discussions about the concept of torch height control and how it works, finding very clear, detailed instructions for installation can sometimes be a bit of a challenge. Users often share their experiences, talking about where they might get stuck or what parts of the process are not quite clear. This is a pretty typical situation when you are working with specialized equipment, where the general idea is known, but the very specific steps for putting it all together might need a little more explanation. So, it is something that people are always looking for more direct help with.

When someone is in the middle of putting in a torch height control, and they hit a snag, it can be a little frustrating, you know? They might have the parts, but figuring out exactly how they all connect or what settings to use can be a puzzle. This is where the community often steps in, with people sharing photos of their setups or offering advice based on their own successful installations. It is a situation where practical, hands-on guidance is very much appreciated, and it shows how much people rely on each other for those specific details when dealing with Langmuir Systems products.

Getting Ready for Your Langmuir Systems Machine - What Tools Might You Need?

For those who are new customers, especially when they are getting ready for their final payment and waiting for their machine to arrive, there is often a lot of thought given to what other things they might need. It is not just about the machine itself, but also about the accessories and bits that help it do its job. People often want to know what kind of tooling to get, or what extra pieces will make their experience smoother. It is a common question, and one that people are always happy to share advice about, which is pretty helpful.

To help with this, some users have put together information or documents that list out suggested tools or items that come in handy. This kind of shared resource is really valuable, as it gives new owners a starting point for what to look for. It is almost like a checklist of things that experienced users have found to be useful, saving new folks some time and guesswork. So, when you are thinking about your Langmuir Systems setup, having these kinds of recommendations can make a big difference in getting ready.

The idea is to help people prepare so that once their machine is there, they can start using it with everything they need already on hand. This could mean different types of plasma consumables, safety gear, or even specific workholding tools. Knowing what to get beforehand can prevent delays and make the initial experience of using the machine more enjoyable. It is, in a way, about making sure everyone has a good start with their new equipment, and that is a pretty good goal to have, really.

Exploring the Langmuir Systems Torch Height Control Module

The torch height control module is a component that many people who use Langmuir Systems plasma tables find very interesting to talk about. It is a piece of equipment that helps keep the cutting torch at a steady distance from the material being cut, which is pretty important for getting a consistent cut line. Discussions often revolve around how this module works, how to set it up, and how it can improve the overall results when making metal parts. It is a topic that brings together a lot of technical questions and practical advice from users.

People often share their experiences with this module, discussing the different ways they have integrated it into their systems. They might talk about the benefits they have seen, like smoother cuts or less material waste. It is a part of the Langmuir Systems setup that can take a little bit of learning to get just right, but the payoff in terms of cut quality is often worth the effort. So, there is a lot of back-and-forth about how to best use it, and what to look out for during installation and operation.

For those who are keen to get the most out of their plasma table, understanding the torch height control module is a key step. It is something that can really change how well the machine performs, and it is a frequent subject of conversation among the user base. People often look forward to working with others in the community to figure out the best ways to use this module, and to help each other with any questions that come up related to their Langmuir Systems needs. It is, in some respects, a very collaborative process.

What is New with the Langmuir Systems Titan 25T CNC Press Brake?

There has been some excitement about the webpage for the Titan 25T CNC press brake going live. This is a piece of machinery that helps bend metal with computer control, making it possible to create very precise shapes for different projects. When a new product page becomes available, it means people can go and see all the details, what it can do, and how it might fit into their workshop or business. It is a pretty big deal for those who are looking for tools to shape metal, and it is something that people have been looking forward to.

You can usually find information about new products like this under the "products" section on the company's main website. This makes it easy for anyone interested to find out more about what the Titan 25T offers. It is a way for Langmuir Systems to show off what they have been working on and to let people know about their latest offerings in the world of computer-controlled fabrication equipment. So, for those who are thinking about adding a press brake to their setup, this is a good place to start looking.

The release of information about a new machine like the Titan 25T sparks a lot of interest among those who work with metal. It suggests new possibilities for what can be made and how efficiently it can be done. People often discuss the specifications, the features, and how it compares to other machines out there. It is, in a way, a moment of anticipation for many who follow the developments in this area, and that is pretty cool to see, really.

How Does a Partnership Benefit Langmuir Systems Customers?

The Langmuir Systems team has shared news about working together with another company, ShopSabre, which is known for its long history in the computer-controlled machine industry. When two companies like this decide to join forces, it often means good things for the people who use their products. ShopSabre, for example, brings many years of experience in designing and building these kinds of machines, which is a lot of knowledge and skill coming together.

This kind of collaboration can lead to new ideas, better products, or even improved ways of supporting customers. It is almost like combining two different sets of strengths to make something even better than before. For customers, this could mean more reliable machines, new features, or perhaps even better ways to get help if they run into a problem. It is a situation where the sum of the parts might be greater than the individual pieces, which is pretty interesting to consider.

When a company with a long background in designing equipment teams up with another, it can really help both sides grow and offer more to their users. It is a way of sharing what each company does best, and then applying that to future projects or current offerings. So, for anyone using Langmuir Systems equipment, this partnership could mean a stronger foundation for the products they rely on, and that is a very positive development, you know, for the long run.

Are There Common Issues with Langmuir Systems Software Updates?

Sometimes, when software gets an update, things do not always go as smoothly as planned. It seems that some people who have moved from an older version, like 21.1.5, to a newer one, have had different experiences. For some, these updates seem to fix problems they were having, which is pretty good news. It is almost like getting a fresh start with the software, and everything just works better.

However, for others, an update might not have the desired effect, or it could even make things a little more difficult. One person mentioned that after updating, their cut quality actually got worse, which is certainly not what anyone wants when they are trying to make precise parts. This kind of situation can be a bit puzzling, especially when the company itself, Langmuir Systems, also finds it hard to figure out why it is happening. It shows that even with the best intentions, software updates can sometimes bring unexpected challenges.

When these kinds of issues pop up, it often leads to people reaching out for help and sharing their experiences with others. It is a reminder that even with advanced machinery, there can be little quirks that need to be worked through, and that is a very common part of using computer-controlled tools. The ongoing process of refining software and making sure it works well for everyone is a big part of what companies like Langmuir Systems do, and it is something that users are always keen to see improve over time, really.